Self Sourcing Chemical: Williston Basin

Self Sourcing Chemical

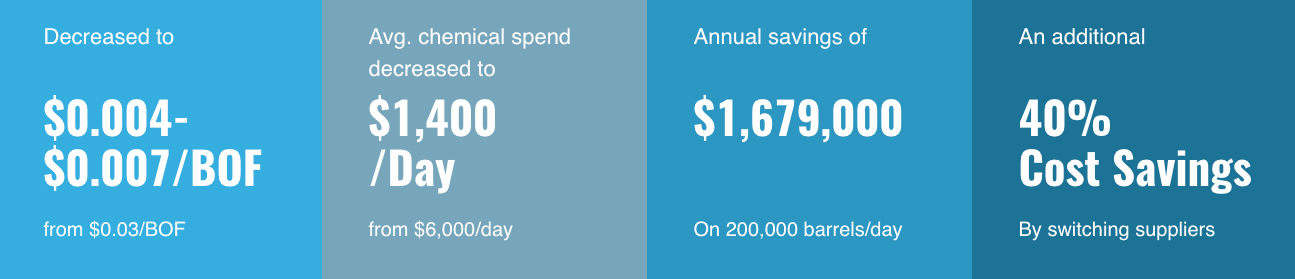

A Williston Basin operator utilizes OLA services to switch from a vendor managed chemical application program to a bulk, wholesale provider.

The Situation:

A Williston Basin operator sought to significantly reduce their overspend on chemical while meeting their goal of completely internalizing their chemical program through wholesale supply.

As in any industry, reducing costs in the oil and gas industry is an ongoing challenge and a top priority. One of the highest operational expenditures required by E&P and midstream companies is chemical. For a typical operator, chemical program costs represent at least 20% of the production operation and can exceed 50% during difficult times. The application of chemistry also requires service, testing and management programs to verify successful methods are in place; this adds to soaring increases in contract costs between chemical vendors and operators.

Removing the service component from the chemical contract can immediately reduce overall chemical cost. Additionally, allowing the chemical vendor to focus on inventory management can improve efficiencies.

Beyond cost reduction, a successful chemical program requires data and analytics to measure and verify success. Realistic budgets and KPIs can only be created by first defining the chemical necessary for well management. In this particular case, OLA stepped in and provided the service, testing, and data analytics necessary for optimized chemical application program management.

The Solution

OLA provided data and analytics through independent well monitoring to optimize the operator’s injection rates and facility management. OLA performance tested products to allow the operator to select the product with greatest financial benefit.

OLA started by testing each well to define its profile and to evaluate the chemical products’ performance. Armed with data and analytics, they quickly discerned the chemical application in place was having almost no effect on stabilizing their wells nor preventing lost injectability of SWD wells. Further, OLA analyzed the facilities — and the resulting insights helped define a proactive chemical program, replacing the traditional reactive approach. Through performance testing, OLA identified the right product to successfully maintain a clean facility and to accept elevated volumes.

Realizing that unbundling the chemical product and service contract immediately removed 1/3 of the cost paid to the chemical vendor, the Company’s management looked for additional avenues to further cut the chemical product cost. They sought out bulk and wholesale chemical suppliers. OLA vetted these products through performance testing and determined an optimal solution.

Key Findings |

#1 Analytical Approach

A data-driven analytical approach was missing from the operator’s chemical management program. OLA’s analyses proved that price was not a measurement tool for the products’ success. Rather, OLA provided key insights to optimize the operator’s production rates and facility management.

#2 Performance Testing

Performance testing products uncovered that most performed at an equal rate and provided similar results. OLA provided a cost equivalency report which allowed the operator to select the product with the greatest financial benefit.

#3 Program Internalization

The internalization of the chemical program allowed the operator to gain full control of their well management. They sourced a lower cost chemical product from a wholesale supplier and removed bias using OLA as a third party, all leading to a successful operation.

The Outcome

Facilities operated efficiently and OLA was able to identify that reduced chemical volume improved the facilities’ performance in separating the water and hydrocarbon. Allowing OLA to provide the insights necessary to make these changes equipped the operator to cut costs, operate efficiently, and regain control of their well management program.

|