Chemical Optimization

OLA provided independent well monitoring to optimize the production chemical program for a large-scale Permian Basin operator, significantly reducing their annual spend on chemicals.

The Situation

Chemical companies are often responsible for “wellness reviews,” which are a routine part of their supplier agreement. In many cases, this service makes up as much as 30% of the cost of the contract. Testing and management of data analytics are often deprioritized due to factors such as labor constraints and inventory management issues. Unfortunately, the operator’s costs are rarely adjusted, meaning they are paying for services not rendered and testing not provided.

In one such scenario, OLA stepped in as an independent provider to aid a large-scale Permian Basin operator in optimizing the production of their wells with proper chemical application and management.

The Solution

Good data and analytics are necessary components to a well management program, and testing is only as reliable and conclusive as the quality of samples collected.

For that reason, the OLA process started on the ground, in the operator’s field, where our team of trained technicians collected high-quality samples according to NACE standards for testing in OLA’s performance laboratory.

-

- The chemical company’s recommended concentration was more than 3X the concentration required

- The chemical company ran two solubilities together when only one was chemically needed

- The chemical company delivered the treatment mixture by continuous injection, but only batch, only batch treatments at lower monthly volumes were necessary

OLA houses the only ANAB ISO-17025 accredited commercial performance laboratory serving the oil and gas industry.

The Outcome

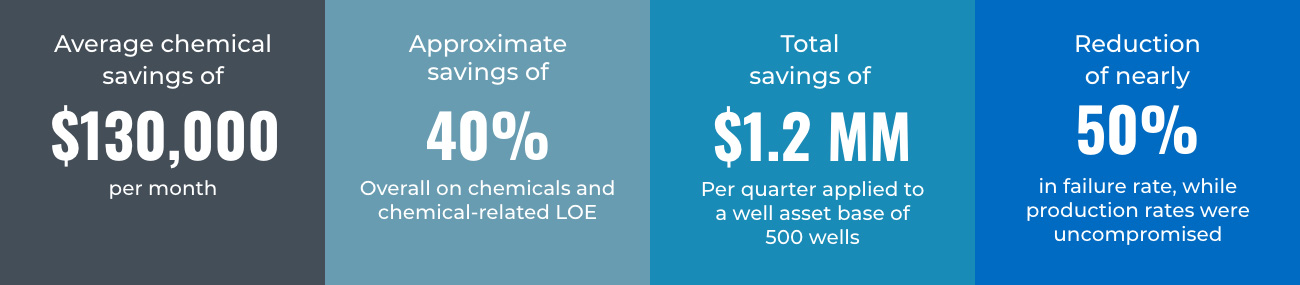

Realizing the wasteful overspend on chemical, missed opportunities to conserve volumes, and improper chemical treatments, the operator trusted OLA for chemical insights and optimized their chemical program.

|

An Eye on ESG

OLA’s improvements to this operator’s chemical program also reduced environmental toxicity by 50%. OLA directly compares SDS sheets of chemicals to validate environmentally friendly insights. We support our customers in making informed, environmentally conscious decisions toward well management.

|

The End Goal

The end goal is the same for every OLA client: gain chemical insights that redefine performance. OLA’s well sampling programs and data analyses drive reduced well failure rates, optimized chemical costs, and improved operational performance.

In most cases, we help operators reach a world of reduced chemical application, including lower overall spend and progress toward your ESG initiatives.

Save chemicals, save money, save the environment.

Production Chemical Optimization